Packaging can be a real money pit. It is often one of the first places that cost-cutting measures are applied, but it is also one of the areas where costs can quickly spiral out of control. And that’s why you must look for effective ways to reduce packaging costs.

Think about your last online purchase. Chances are, the product arrived in some packaging, not just a plain cardboard box.

Air pillows, packing peanuts, and bubble wraps ensure your purchase arrives safely and sound. While this extra protection is necessary for delicate items, it also drives up the cost of shipping.

Packaging expenses may not be on your mind when planning a small order, but as your business grows and you need to ship products with more complex or fragile packaging, it contributes to higher costs. Packaging can increase the price per item and even affect item quality.

However, you shouldn’t think about cutting down packing costs as simply trimming the fat and instead consider how to make smarter product packaging choices. Sometimes, how something gets packaged matters just as much or more than what’s inside.

Take the example of Apple. Their consumers always unbox the products with great excitement even though the company doesn’t use over-the-top flashy packaging designs like other tech companies do. It’s always pretty unique and clean.

So, in this article, we’ll walk you through several cost-effective packaging methods to reduce costs. But, first, let’s understand the different packing expenses when package pricing can increase to get the basics right.

Table of Contents

Types of Packaging Costs

There are many different types of packaging expenses that you should consider. For example, there are materials, labor, transportation, and storage expenses.

All these factors can add up quickly, so it’s essential to be mindful of them when making packaging decisions.

Cost of Materials

This includes the cost of the actual packaging materials and any other materials needed for assembly or protecting the product during shipping.

For example, if you’re shipping a fragile item, you’ll need to factor in the cost of bubble wrap or other padding material.

Labor Expenses

Labor costs are also an important consideration. This includes the cost of your employees’ time spent on packaging and any outsourced labor expenses. Include their fees in your calculation if you’re using a fulfillment company.

Shipping Costs

Transportation costs include fuel, surcharges, or other fees associated with your chosen transport method.

Storage Expenses

Finally, don’t forget to account for storage costs. If you’re storing products long-term, you’ll need to factor in the warehouse space price and the cost of keeping your products safe and secure.

Waste Costs

It is the cost of disposing of any damaged or unused packaging.

Want to See For Yourself How RouteMe Can Reduce Packaging Costs?

What Factors Contribute to Higher Packing Costs?

Here are some factors which can increase packing costs.

- Long processing times: If processing your packaging takes a lot of time, you need to spend more money producing it.

- Poor packaging materials: If the packing materials you use aren’t sturdy enough to make sure your products do not get damaged, it can increase packaging costs.

- Weight: Heavier packages cost more to deliver because they require more transportation resources (i.e., fuel).

- Distance: Longer distances obviously cost more to ship than shorter ones.

- Value: This one is a bit trickier because it’s not always easy to determine the value of something. But in general, pricier items cost more to transport than cheaper ones.

- Shape: If the shape of a package makes it challenging to fill container space, the price will be higher.

- Weather: The weather can significantly impact how much it costs to deliver a package. For example, if a package has to be shipped during a heat wave, the cost will be higher than if it were delivered during a cold snap. That’s because heat waves can cause delays at shipping hubs, adding to the shipping cost.

- Handling: Packages with fragile or hazardous materials require special care for handling, so the prices for such packages are higher than standard packages.

How to Reduce Packaging Costs

Here are a few ways to keep a lid on your packaging cost.

Choose the Right Packaging Materials

If you’re looking to reduce packaging costs, you need to choose the right packing materials. There are many options, and knowing which ones are right for your product can be challenging. So, here are five tips to help you get started.

- Consider product weight: Heavier products will require more robust packaging materials, which will be more expensive. Choose rigid packaging materials to support your product, but don’t overdo it, or you’ll spend more than you need to.

- Think about the size of your product: If you’re selling smaller items, you don’t need to use oversized packaging. That’ll just add to your expenses. Choose packaging that’s the right size for your product, and you’ll save money.

- Consider the environmental impact of your packing materials: Some materials are more sustainable than others, and using them can help reduce your carbon footprint. If you’re looking to be eco-friendly, choose to package made from recycled materials.

- Choose durable materials: You don’t want them to fall apart before your product gets to the customer. Choose materials that won’t tear or break easily and protect your product during shipping and handling.

- Compare prices before you buy: Packing materials can vary widely, so it’s important to compare options before making a purchase.

Optimize Delivery Routes

Anyone who’s ever ordered something online knows the drill: after a few days (or sometimes even hours), a package arrives on your doorstep, often containing just a single item. And while it’s nice to get our purchases so quickly, all that packaging can increase expenses and take a toll on the environment.

But there is a way to reduce the amount of packaging used without sacrificing speed or convenience, and that’s route optimization.

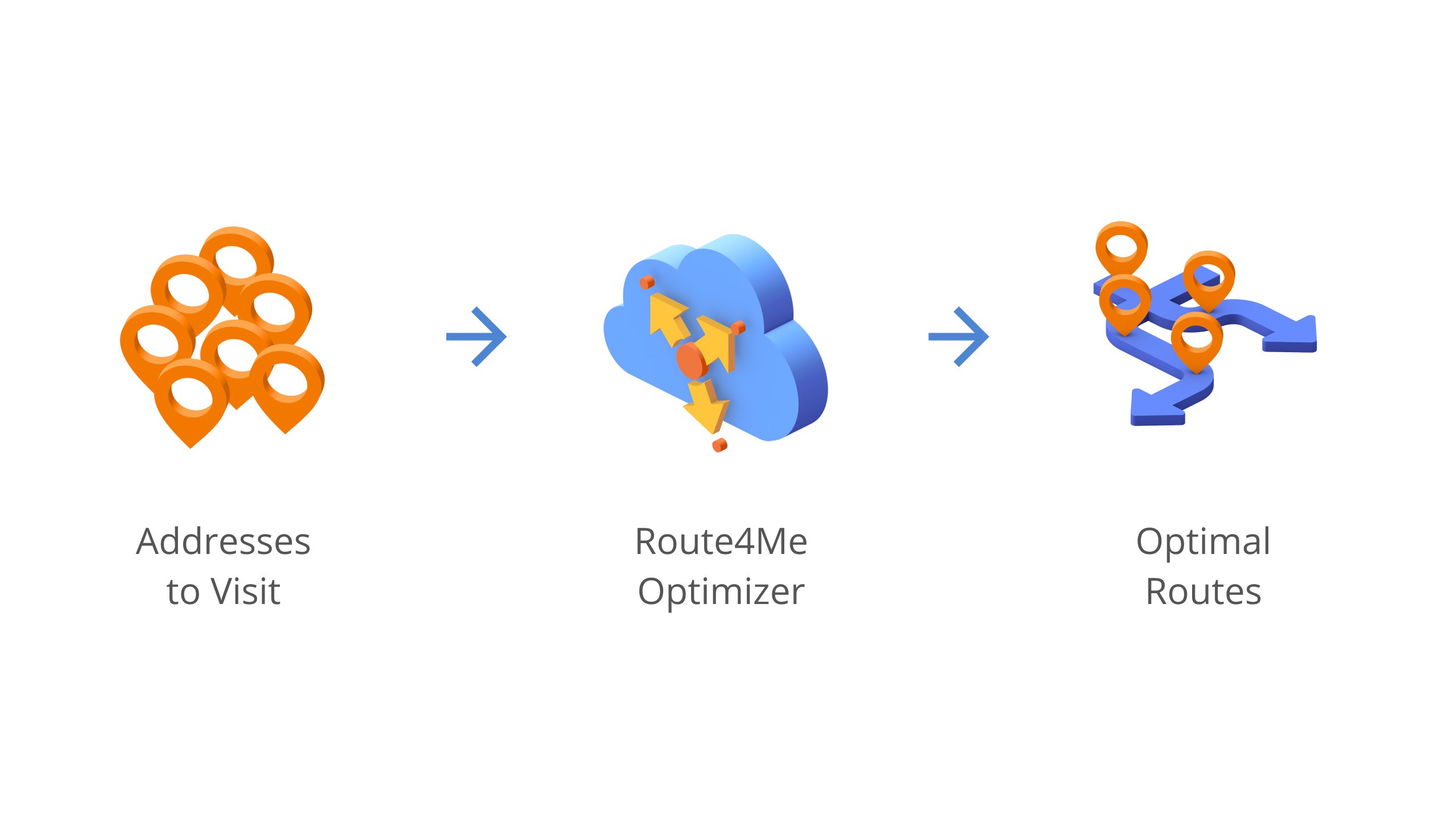

Vehicle routing software can help you to avoid costly delays by planning the most efficient route possible. With a map route planner like Route4Me, you can import orders in bulk and, within a minute, plan well-optimized routes for your entire fleet.

Route4Me route planner helps you group orders to similar addresses and reduce the number of trips your drivers have to make, reducing the amount of packaging material needed.

The delivery management software’s ability to consolidate multiple shipments into one trip saves fuel costs and reduces wear and tear on your vehicles.

You can schedule routes during route planning, reschedule already active or optimized routes, and even optimize routes for recurring delivery schedules. Learn how Route4Me can help with schedule optimization.

Want To See For Yourself How Route4Me Can Boost Your Profits?

There are many other features and benefits of route optimization software that can make delivery operations management seamless such as:

- Customer Portal lets your customers track their delivery status in real-time.

- Customer alerting and notification helps you notify customers thru SMS or email whenever their order is out for delivery or near their location.

- eSignature to facilitate digital proof of delivery.

- Driver breaks to reduce driver fatigue and improve productivity.

- GPS tracker to monitor your vehicle movements on the road in real-time. Learn the top ten benefits of GPS tracking.

Learn the top eight benefits of delivery scheduling software.

![]()

Automate Packaging Process

Automation is everywhere. You can use a robot to mow your lawn, vacuum your floors, and even deliver your groceries. So why not automate the packaging process?

Doing so can reduce your packaging costs while ensuring that your products are adequately protected.

Using machines to do the heavy lifting can eliminate the need for costly manual labor and free your employees to do more interesting (and less tedious) tasks.

In addition, automating your process reduces the time it takes to package the products and improves efficiency and accuracy, leading to fewer mistakes and less waste. And best of all, it’s easy to do! Here’s how:

- Invest in a good quality automated packaging machine: There are many different types of devices available on the market, so make sure you choose one that will fit your needs.

- Set up your packaging line efficiently: This will help you save time and money by reducing packing times.

- Train your employees on how to use the automated packaging machine: This will ensure that they can operate it properly and avoid any potential accidents.

Consolidate Orders to Reduce Packaging Costs

If you’re ordering multiple items from different suppliers, see if you can get them to ship the items in one box. This will lead to significant savings on both shipping costs and packing materials.

Keep Your Packages Small

Try to keep your packages as small as possible. Smaller packages often have less fragile items inside, making them less susceptible to transit damage.

They’re also more likely to fit through the letterbox, so there are fewer chances of missed deliveries. Plus, the smaller the package, the less it will cost to ship.

Remove Inserts

Inserts are those little pieces of paper that come with the product with all sorts of information. You know, like the warranty, the business’s contact information, and that weird message from the CEO that no one ever reads.

This is important, but it doesn’t need to be in the package itself. Printing it inside your product box or including a hot-stamped design to reduce costs is much cheaper.

Audit Your Packaging to Reduce Your Packing Expenses

It’s easy to let packaging costs get out of control without even realizing it. That’s why it’s crucial to audit your packaging regularly.

By closely examining your packaging, you can identify areas where you spend too much or use needlessly costly materials.

In some cases, you may be able to reduce packaging costs simply by making a few minor changes. For example, using less padding in your boxes or switching to a different type of shipping label.

The best practice is to schedule a packaging audit every quarter or six months to reevaluate your packaging methods and supplies.

Use Custom Packaging to Reduce Costs

Packaging costs can add up quickly – especially if you’re using off-the-shelf packaging solutions. One way to reduce your packing expenses is to use custom-sized packaging.

Custom packages are specifically tailored to your product. This can result in more efficient use of materials, saving you money in the long run. And because custom-sized packaging is made to your specifications, you can be sure that it will fit your products perfectly – eliminating the need for costly returns or replacements. In addition, custom packaging provides a competitive advantage.

Negotiate with Your Packaging Supplier

Your packaging supplier may be able to give you a better deal if they know that you’re serious about reducing your costs.

Final Thoughts about Reducing Packaging Costs

There are many ways to reduce packaging costs without compromising quality or your brand. Use recycled materials, reuse packaging whenever possible, simplify your packaging design, and shop around for the best prices on packaging materials.

You can also compare quotes from different packaging vendors, negotiate with vendors for better rates, take advantage of bulk discounts, and use online resources to find coupons and promo codes for packaging supplies.

You must also leverage an advanced multi-stop route planner to optimize your logistics. A delivery route planner can help you improve driver productivity, reduce fuel costs, and increase revenue per driver.

Begin your free 7-day trial of Route4Me today to reduce shipping costs and make your delivery operations efficient.

Want to See For Yourself How RouteMe Can Reduce Packaging Costs?