In delivery logistics, the last mile often steals the spotlight, even though the first mile is equally essential.

Take a look at the Google Trends report below. It shows how ‘last-mile delivery’ searches on Google have skyrocketed over the years compared to first-mile searches.

It’s not without reason because efficient last-mile delivery impacts customer satisfaction and profitability.

However, first-mile delivery, the first leg of the journey, set the tone for the entire supply chain journey.

Delays or inefficiencies in first-mile delivery can snowball, impacting everything from how quickly you can deliver a package to how much it costs your business to ship it.

But what exactly is first-mile delivery?

Why is it so crucial?

And how to optimize it?

We discuss these and many more below. So, let’s get started.

Table of Contents

What is First Mile Delivery?

First-mile delivery typically refers to transporting finished goods from the point of origin, such as a manufacturing or production facility, to the next destination.

It is the first step of order fulfillment. It involves multiple stakeholders, including shippers, carriers, drivers, and sometimes third-party logistics providers (3PL).

However, it could mean different things for different industries.

For example, first-mile delivery could mean delivering goods from a regional warehouse to local stores or distribution centers for retailers.

For a logistics service provider, the first mile operations could involve picking up orders from the shipper and then delivering them to the consignee.

For moving and storage companies, the first mile could also mean picking up inventory from the store or customer’s home and returning it to the storage site or warehouse.

No matter your industry, the first-mile delivery process could be complex.

It involves loading and unloading shipments multiple times, different drivers managing the same items, and coordinating shipments from retailers and eCommerce shippers.

Multi-Stop Route Planner App

First Mile Vs. Last Mile Delivery – The Differences

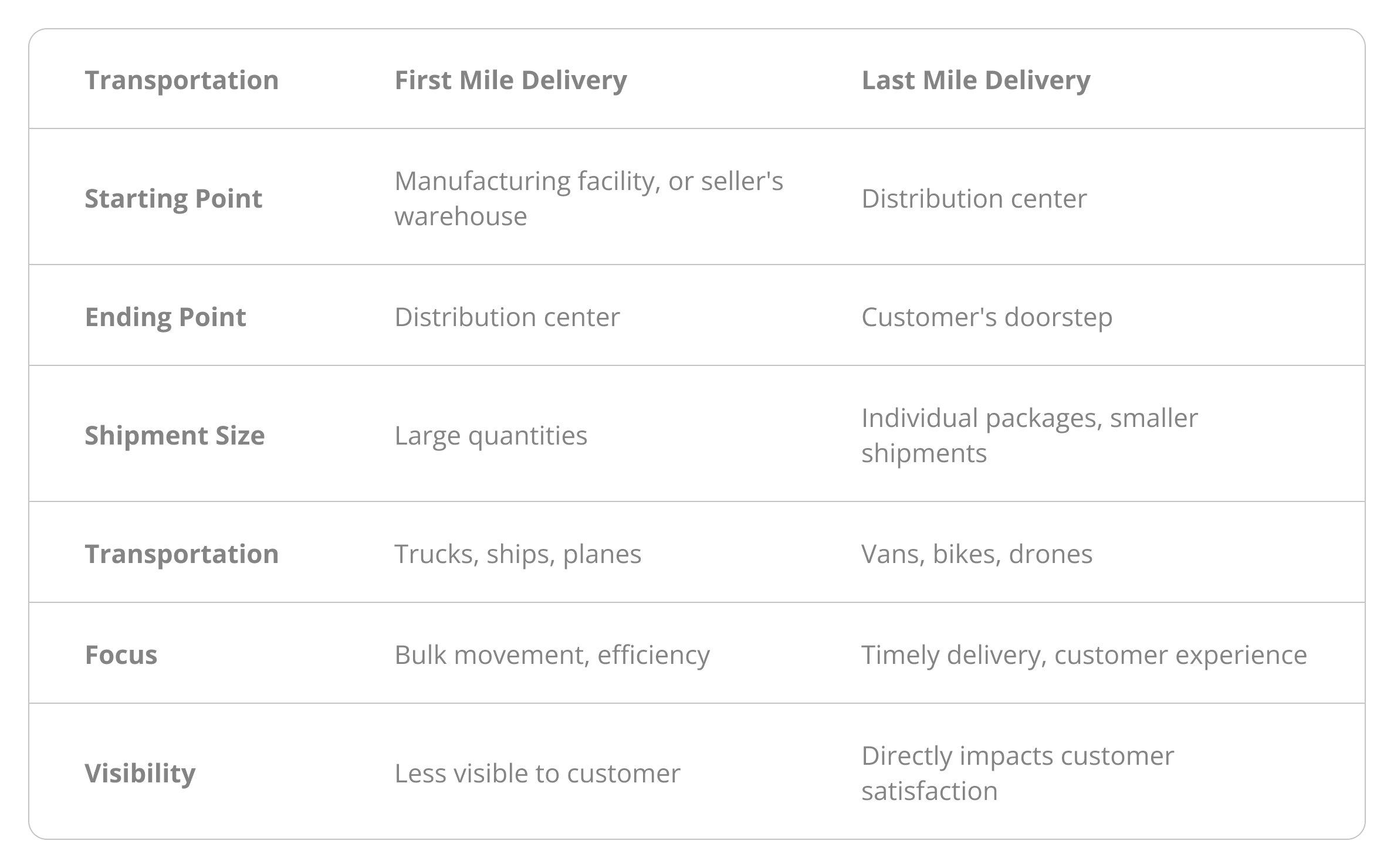

The first mile is the first leg of the delivery journey. In this case, goods are typically moved in bulk, often on large trucks, from a factory or production plant to a central distribution center or store. This stage happens behind the scenes, so there is little or no chance of customer interaction.

The last mile is the final leg of the delivery journey. It involves transporting individual packages using small vehicles, such as vans, from the distribution center directly to the customer’s doorstep or a pickup point. This final mile directly impacts the customer experience.

Here is a table summarizing the key differences.

Why First Mile Delivery is Important

Here are several detailed reasons why you shouldn’t ignore first-mile delivery.

Improve Efficiency

First-mile delivery can create a Domino effect, delaying everything that comes after it. Therefore, you must manage it efficiently to speed up the entire process and meet customer expectations.

Reduce Transporation Expenses

Efficient first-mile delivery reduces the time and distance required to deliver goods from the point of origin to distribution centers.

By optimizing routes, consolidating shipments, and maximizing vehicle capacity, you can reduce fuel consumption and costs.

Seamless Integration with Supply Chain Stakeholders

First-mile logistics is a crucial link between various stakeholders in the supply chain, including suppliers, manufacturers, delivery service providers, and distributors.

Seamless integration and coordination between these parties are necessary to ensure seamless operations and timely delivery to distribution centers or transportation hubs.

Effective Inventory Management

Efficient first-mile delivery helps manage inventories more effectively. It prevents stockouts and overstock situations, facilitates better demand forecasting, and improves resource allocation.

Improve Customer Satisfaction

Customer satisfaction isn’t solely tied to final-mile delivery. Delays or inefficiencies in the first mile can ripple down the supply chain, causing late deliveries and unhappy customers.

As logistics professionals and supply chain managers, your role in ensuring efficient first-mile delivery is critical to maintaining customer loyalty.

Reduce Carbon Footprint

First-mile optimization can reduce carbon emissions and minimize the environmental impact of transportation operations.

By consolidating shipments, optimizing routes, and adopting eco-friendly delivery practices or vehicles, you can promote sustainability in entire supply chain operations.

Challenges of First-Mile Delivery

Several obstacles can significantly impact first-mile delivery, and it’s crucial to be aware of them. Understanding these challenges can help you to improve and innovate in your first-mile delivery process continuously.

- Traffic congestion poses a significant challenge, causing delays in pickup and delivery. Due to the high traffic volume, delays are more evident in urban areas.

- Sudden changes such as rerouting or rescheduling can disrupt the first-mile delivery and increase operational expenses.

- Lack of real-time visibility often makes determining the exact location of packages in transit difficult.

- There is always a risk of theft, tampering, or damage during transportation. Hence, it is critical to ensure the security of packages from the origin to the local distribution center.

5 Best Practices to Optimize First-Mile Delivery

1. Use Route Optimization Software

Route planning using pen and paper or a spreadsheet is purely guesswork.

How would you know which area has a mile-long traffic jam due to a sudden accident? Or which areas have thunderstorms?

How can you adjust the delivery schedule quickly to accommodate last-minute changes?

Therefore, a route planner like Route4Me can be used to plan efficient routes for first-mile delivery. Such software considers traffic, weather, roadblocks, and delivery schedules that could impact the deliveries.

Implementing a delivery route planner like Route4Me can significantly optimize your first-mile delivery. It reduces travel time and fuel expenses, helps ensure entire on-time deliveries, and improves drive productivity.

You can even plan routes that change daily, weekly, or seasonally. Plus, it enables you to re-optimize routes within seconds to satisfy last-minute customer requests.

Want To See For Yourself How Route4Me Can Help Plan Efficient Routes?

2. Implement Tracking System

Use a tracking system to get a bird’ s-eye view of your delivery operations and inventory management, which can help you make faster and better delivery decisions.

For example, use a barcode scanner to quickly and accurately scan inventory as it arrives at your warehouse or distribution center.

You can also use GPS tracking software to monitor real-time vehicle movements to ensure the goods arrive at the distribution centers on time.

Route4Me offers a built-in commercial GPS tracker and integrated barcode scanner, so you don’t need to purchase separate software.

You can also use a warehouse management system (WMS) to monitor inventory levels in real-time and ensure products are stored in the most efficient locations.

All these tracking systems help you with better control and increased transparency and make you trustworthy to your customers.

3. Automate the Process

Automate your first-mile delivery operations to improve loading efficiency and make delivery faster.

You can audit your team’s tasks to identify areas that need to be automated. You can also ask for feedback or look for repetitive processes. This would make your team happy, as you would make them feel valued and reduce attrition.

Automation also minimizes errors and improves service quality.

For example, when using an advanced multiple-stop route planner like Route4Me, you don’t need to enter data manually into the system, which is prone to human errors. You just need to upload the final destination addresses into the system, and the software will take care of the address and route accuracy.

Plus, you don’t need to call your drivers to ask about their whereabouts en route. You can automatically monitor their location on a map in the software.

4. Create a Warehouse Receiving Process

Another best practice is developing a thorough warehouse receiving process, which is critical for accurate inventory tracking. This process outlines how your warehouse team will receive inventory shipments from the supplier.

Start by identifying the total quantity of each item that will be delivered, the number of containers, and the packaging requirements for each use. These include the number of packages loaded per pallet, labeling criteria, and acceptable package weights and sizes.

Meet with the shipper, unload the necessary cargo, and double-check the inventory received against the paperwork. Store in a way that will speed up warehouse picking.

5. Collect Relevant Data

Data can be your best pal to optimize your logistics process.

Gathering and analyzing critical metrics such as time to stock and ship and transit damage rates can help you find bottlenecks in your supply chain and make informed decisions about optimizing the initial leg of the delivery journey.

Frequently Asked Questions (FAQs) about First-Mile Delivery

What is the difference between the first mile and middle mile ?

What is first-mile, middle-mile, and last-mile delivery?

Conclusion about First-Mile Delivery

Though often overshadowed by last-mile, first-mile delivery is critical to the supply chain process.

By understanding and addressing its unique challenges, you can optimize the supply chain from the outset.

Integrate efficient first-mile strategies with robust middle-mile and last-mile processes to ensure a seamless, end-to-end delivery system that meets customer expectations and helps you stay ahead of competitors.

Want To See For Yourself How Route4Me Can Help Plan Efficient Routes?