Construction equipment theft is a billion-dollar crime in the United States! According to one report on equipment theft, the construction industry loses more than $1 billion every year to equipment theft and the recovery rate is just 21%. Since the recovery rate is so low, a theft may translate into a significant loss that offsets the gains in your construction business. For example, you may have to pay the costs of replacing the stolen equipment, you may have to pay a larger insurance premium, your project may get delayed, and you may end up losing a customer.

Is there a solution to the problem? Yes, using GPS trackers to protect your heavy equipment will give you the much-needed peace of mind!

GPS trackers will do more than just equipment monitoring. It can also keep your workers safe on-site, monitor on-road driver behavior in real-time, ensure employees’ adherence to onsite safety requirements, and monitor fuel consumption. Below are five benefits of using GPS tracking for your construction equipment.

#1 Prevent Theft

What can be more helpful in the event of theft than knowing the exact location of your stolen equipment? Features like real-time tracking and geofencing in GPS trackers can help you with lost vehicle tracking. For example, in case of a theft, the GPS tracking device will provide you with real-time data on the equipment’s movements. The police can then intercept the equipment’s location, using GPS asset tracking, and recover the stolen asset with ease.

With the geofencing feature, you will also be alerted the moment your equipment leaves the construction site. The feature can also alert you when the equipment is being used or the engine is turned on outside work hours as this would be an indication of someone trying to misuse or steal your equipment. Some GPS trackers for heavy equipment even allow you to prevent the engine from being started or shut it down remotely if unauthorized use is detected.

#2 Reduce Fuel Costs

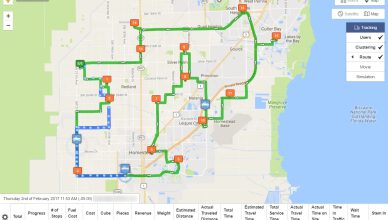

Using GPS tracking for construction equipment, you can help your drivers plan the shortest or fastest route to work. This will certainly decrease your fuel costs.

Reckless driving also increases fuel consumption. In addition, bad driving habits increase the chances of accidents happening and, if an accident does happen, there are also operational losses due to vehicle downtimes and missed deadlines.

Luckily, with a GPS tracker, you can monitor your drivers’ driving habits in real-time on the road and set alerts for unsafe driving habits. You can then discuss any bad driving behaviors and train your drivers on safer habits. This will drastically reduce your fuel costs and reduce your drivers’ chances of getting into an accident.

Want To See For Yourself How Route4Me Can Boost Your Profits?

#3 Monitor Drivers’ Behavior

From transporting material from one site to another to driving waste to a landfill, construction work often involves lots of driving. So, how do you track the large number of drivers working on-site and off-site? Also, are they taking prolonged breaks or indulging in bad driving habits? Investing in GPS tracking for construction equipment will help you here.

GPS trackers for machinery can provide real-time reports and notifications on the speed at which a vehicle is moving. It also monitors whether the driver accelerated beyond the allowed speed limit or violated traffic laws. You can also track whether a driver is taking unscheduled breaks, using your business vehicle for personal use or taking detours. In addition, you can monitor onsite activities like overloading a machine and making sharp turns, which are considered safety hazards and may lead to equipment tipping and rollovers. Construction equipment tracking will further help you identify workers who are misusing equipment so you can train them on the correct usage.

Just having a GPS tracking device for construction equipment in place could encourage a safety-conscious culture at your site. When your workers and drivers know that their activities are being monitored, they will be more alert and conscious of their behavior.

#4 Ensure Workers’ Safety

Vehicle-related fatalities were a leading cause of death at job sites in 2017. These heavy equipment accidents could have been avoided with proper training and surveillance.

GPS trackers with geofencing capabilities can help you monitor the movements of onsite employees to keep them safe. Using geofencing, you can create a virtual boundary around a specific location, within or around your construction site. Once you have set up the virtual fence, you will receive alerts whenever a worker or equipment enters or exits the designated area.

With geofencing, you can also create outward-facing or inward-facing fences. Outward-facing fences keep workers and equipment inside the defined location. For instance, you can mark geofences around an area to ensure that heavy machinery stops working when it exits the designated area. Inward-facing fences keep workers and equipment out of a restricted area. For instance, you can use asset trackers with the geofencing feature to create lower-speed zones in specific areas on your site or to keep drivers out of ‘restricted’ zones.

Monitoring workers’ physical location on-site and using location data to prohibit them from entering or exiting specific areas can strengthen their safety.

#5 Cut Insurance Costs

Without GPS equipment tracking, the police may take weeks to track down stolen equipment, if they ever find them. Thus, insurance providers often end up paying out large claims. And, since GPS tracking for construction equipment helps companies recover stolen equipment, many insurance providers offer discounts to construction companies that implement it. The actual discount may vary depending on the provider and your record, but some construction companies have been saving significant amounts on insurance costs by merely installing GPS devices.

In addition to such one-time insurance discounts, installing GPS tracking for construction equipment also helps you save on your insurance premiums. A GPS tracking system helps improve driver behavior which means fewer speeding tickets, accidents, and claims. All of this contributes to keeping deductibles and premiums lower.

Conclusion

With construction equipment costing big bucks, the assets are worth protecting. In the event of a theft, the cost of replacing the equipment is just the beginning; missed project deadlines, insurance dilemmas, and lost customers will follow. Using GPS tracking for construction equipment can save you from all that. Just attach GPS machinery tracking devices to your assets and trust the technology to do the rest.

Want To See For Yourself How Route4Me Can Boost Your Profits?